| ELC Line Conditioner&Energy Saver General Features | ||

|---|---|---|

| Power (kVA) | 120 kVA | |

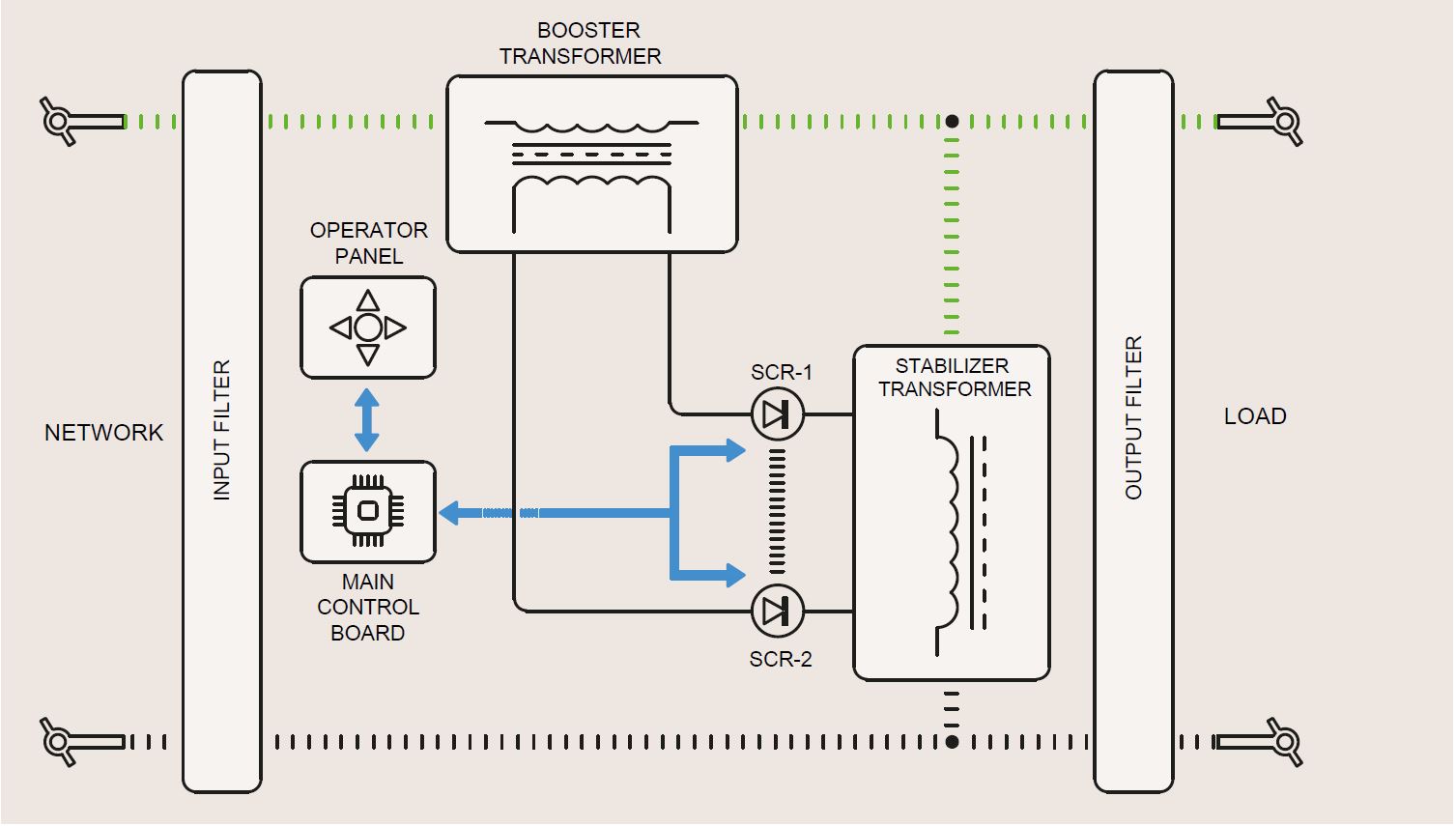

| Technology | Thyristor Technology, High-speed Voltage Regulation, Maintenance-free design | |

| Input | ||

| Rated Input Voltage | 3 Phase Model: 400VAC 3Phase+Neutral+Ground (Different voltages are optional) | |

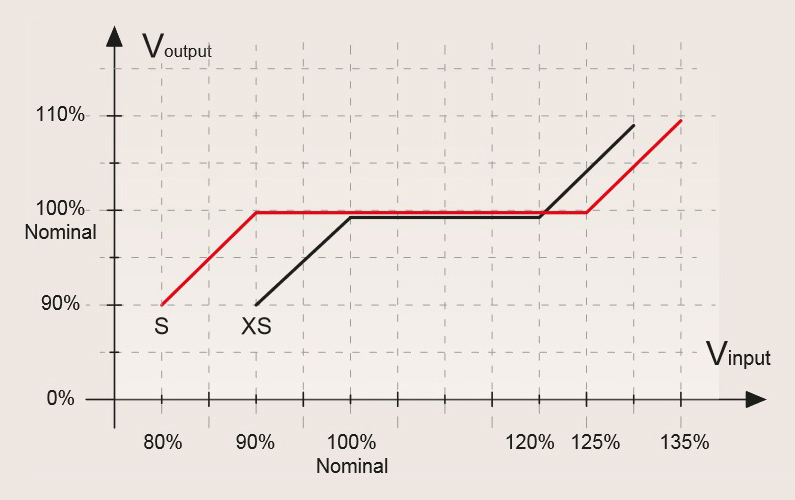

| Voltage Tolerance | XS Model +%20 S Model -%10 , +%25 | |

| Frequency | 50 Hz. +/-%5 (60 Hz. Optional) | |

| Output | ||

| Rated Output Voltage | 3 Phase Model: 400VAC 3Phase+Neutral+Ground (Different voltages are optional) | |

| Voltage Tolerance | +/-%2 | |

| Frequency | 50 Hz. +/-%5 | |

| Overload Capacity | 125% 1 minute, 150% 10 seconds, 151% and above 0.2 seconds | |

| Response Time | 20 msec | |

| Correction Time | 100msec-200msec. | |

| Efficiency | > 97% typical | |

| Network Filtering and Energy Saving Options | ||

| 8Energy Savings calculation and monitoring software | Special software developed to measure and monitor the Actual Saving rate | |

| Harmonic Filter Unit (Optional) | Passive Harmonic Filter specially designed for the project (designed according to the measurement report) | |

| EMC Filter Unit (Optional) | EMC filter for protection and high performance of sensitive electronic equipments | |

| Automatic By-Pass (Optional) | Automatic by-pass system to work in ECO mode in case of Low Voltage and Low load. | |

| Management Monitoring and Communication Interfaces | ||

| Operator panel with LCD Display | Input Voltage, Output Voltage, Load Percentage, Frequency, Status Information, Fault Information, Parameter settings | |

| Remote Management Interface (optional) | Browser-based remote management with Ethernet connection MOD-BUS RTU with RS485 connection | |

| Protection Functions | ||

| Voltage Protection | Electronic protection for Low Voltage and High Voltage | |

| Current Protection | Input Circuit Breaker (Output Circuit Breaker optional) | |

| Overload Protection | Electronic Overload Protection (1 minute at 125% overload, 10 seconds at 150% overload, at >151% overload the power to the load is cut off after 0.2 seconds.) | |

| Over-Temperature Protection | Electronic Over-Temperature Protection (Fan cooling works at 50°C. At 80°C, the power to the load is cut off.) | |

| Over -Voltage /Surge Arrester | Over-Voltage Protection Surge Arrester Class-I or Class-II (optional) | |

| Environmental Conditions | ||

| Operating temperature | -10 °C ~ +40 °C | |

| Altitude Operating Height | 1.500m | |

| Humidity | 90% none condensed | |

| Acoustic Noise | < 65dB (at 1m distance and doors closed) | |

| Cabinet Specifications | ||

| Type – Protection Class | Free Standing Modular Cabinet, IP21 Indoor type | |

| Paint – Color | Epoxy-Polyester Powder Paint - RAL 7032 | |

| Cooling | Forced air cooling with thermostat controlled fan | |

| OPTION | CODE | DESCRIPTION |

|---|---|---|

| Non-standard Operating voltage value | xxxV | ELC series voltage regulators can be produced at any required operating voltage value. |

| Non-standard operating voltage range | XS,S | ELC series voltage regulators can be produced at different input voltage range. The required levels must be stated clearly by the order confirmation. Maximum input voltage range: -%60, +%40 |

| Non-standard output voltage tolerance | 4T,5T, 4C,5C | Output voltage tolerances of ELC regulators can be +/-1%, +/-2%, -3%, +/-5% |

| Adjustable output voltage | ADJ | Output voltage of VOR series regulators can be adjusted by the LCD panel. Maximum adjusting range is +/-15% |

| Non-standard frequency | FRQ | ELC series voltage regulators are produced to function with 60Hz network frequency. |

| Output protection MCCB | OCB | Optional MCCB may be added to the regulator output to provide additional protection.r |

| Reactive Power Compensation System | RGS | Reactive Power Compensation System can be added recording to customer needs |

| Maintenance By-Pass Switch | MBP | A Maintenance By-Pass switch can be added to the ELC Line Conditioner&Saver, which ensures that the loads are transferred to the grid in case of maintenance or failure. Maintenance By-Pass switch is an I-0-II position changeover switch and is manually controlled. During the Maintenance By-Pass operation, the power to the loads is cut for a short time. |

| Harmonic Filter | HF | Harmonic filters specially designed for the project to eliminate the negative effects of harmonic distortions and increase efficiency connect to the input or output of the ELC. Filter needs and features are evaluated separately for each project. |

| Automatic uninterruptible By-Pass | ABP | Automatic Uninterruptible By-Pass unit may be added to the output of VOR series voltage regulators. |

| Isolation Transformer | TRF | Isolation Transformer or Voltage Changing Auto-Transformer can be supplied for both input and output of VOR series voltage regulators. Reguired transformer specification must be given by the order |

| Special enclosure | K | VOR series voltage regulators can be produced both INDOOR and OUTDOOR in special cabinets having different IPXX protection classes. |

| EMC Filter | EMC | Specially designed EMC-Filters can be added optionally to the both input and output of VOR series voltage regulators. Filter specifications must be stated by offer/order. |

| Surge Protector | SPD | High-Voltage Protection and Surge Arrester can be added to the both input and output of VOR series voltage regulators. The required protection classes and the specifications (CLASS-I, CLASS-II, SLASS-III) must be given with the order. |

| Remote monitoring and management unit | RMU | For remote monitoring and managing of VOR series voltage regulators, Remote Management and Monitoring unit can be added optionally.No any other software is needed for this RMU unit which provides a browser based communication over LAN- connection or internet. |

| Dry contacts | C | NO-NC dry contactor sockets can be applied for ON-OFF and Automatic By-Pass modes of the regulators. |

| Non-standard Input/Output terminal | T | According to the various customer needs. Input and output terminals can be designed and located specially on the cabinet. The required terminal drawings must be supplied together with the offer/order. |

| Special design and accessories | SPM | VOR voltage regulators can be designed specially with respect to direct customer needs and teachnical specifications. All special requirements and detailed teachnical drawings and specifications for accessories must be provided by the customer at the offer/order stage. |

| Parallel connection management unit | PCM | Up to 4 svs units can be connected in parallel for special high power aplications. A PCM unit is used for management and syncronization when svs unit are connected in parallel. |

| Special operating temperature | SOT | Custom device these can operate in special operating temperatures can be manufactured on demand. |

| Wooden Case | WCR | Wooden case and special packaging compatible with international shipment standards |

|

Document Name

|

Download

|

|---|---|

| ELC | ELC English Catalog |