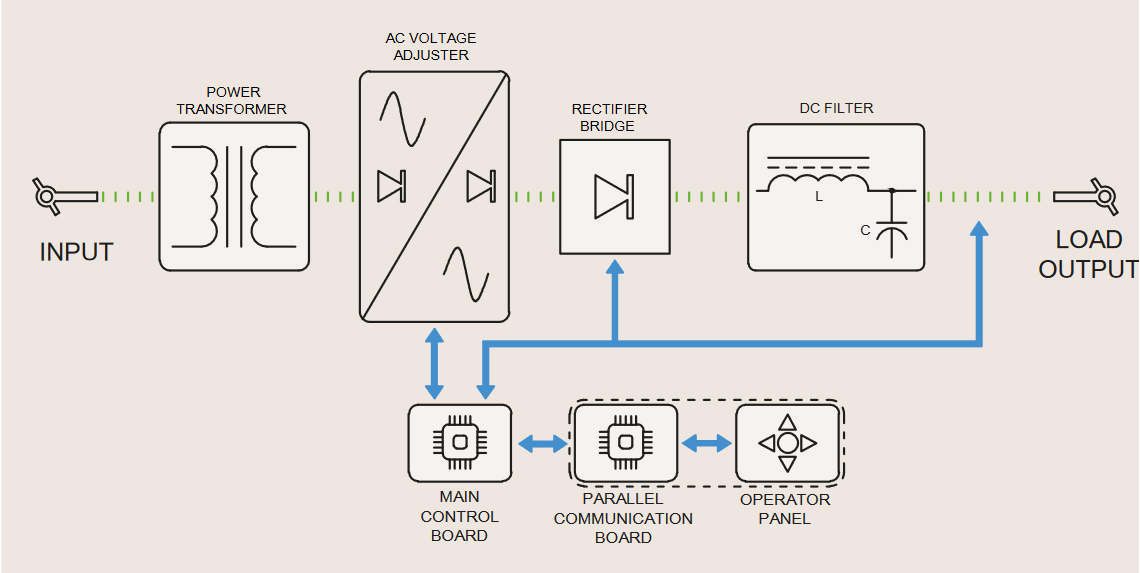

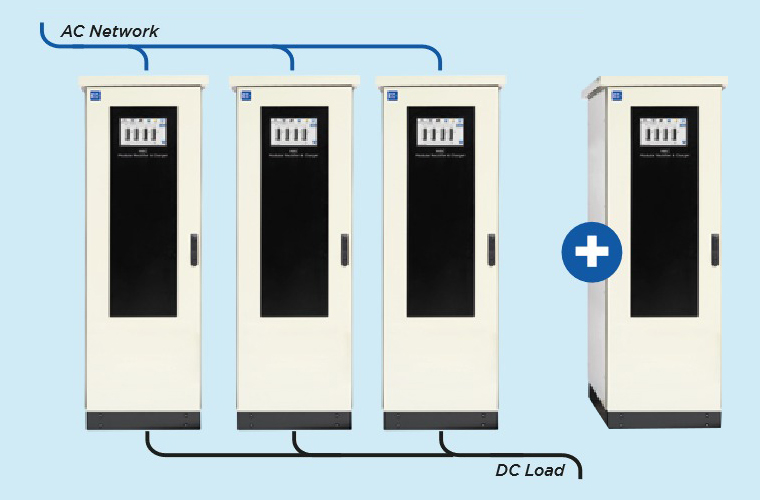

The MRC rectifier is designed for applications that require high power adjustable DC voltage. Many MRC rectifiers are connected in parallel to provide a very high power rectifier-charger solution. Output voltage and output current are adjustable between zero and nominal value. It is suitable for using in projects that require High Power and High Current, in universal battery charging and DC supply applications that require adjustable output voltage and output current, in projects that need parallel connection and redun-dancy, and for industrial DC motor supply.

●Rectifier and Battery Charger that can be connected in parallel

●Multi-master Parallel Connection Technology

●Adjustable Output Voltage between 0V-1000VDC

●Parallel connection up to 16 units

●High power solution up to 10 MVA

●Equal Load Sharing

●Input Isolation Transformer

●Durable structure with thyristor technology

●Production at all industrial input voltages

●Ni-cd, Lead Acid and Stationary battery charging

●DC Earth Leakage protection

●Low Voltage / High Voltage protection

●Overload protection

●Over temperature protection

●Efficiency >% 95

●7” Touchscreen Operator Panel

●Suitable design for industrial environment

●TS EN ISO 9001: 2015 Quality Certified

| MRC Modular Rectifier and Battery Charger Technical Features | |

|---|---|

| Technology | Parallel Connectable, Multi-master Rectifier and Charger |

| Number of Parallel Connection | It can be connected in parallel up to 16 units |

| Unit Power | 600 KVA |

| Input | |

| Rated Input Voltage | 400VAC 3 Phase + Neutral + Ground (Different voltages are Optional) |

| Voltage Tolarance | +15 % , -15 % |

| Frequency | 50 Hz. +/-%5 (60 Hz. Optional) |

| Output | |

| Nominal Output Voltage | 1000V DC |

| Voltage Tolarance | +/-%2 |

| Voltage Adjustment | It can be adjusted between 0% - 1000V% nominal |

| Nominal Output Current | 600A |

| Soft Start | Adjustable between 0 – 30 seconds |

| Current Adjustment | Adjustable between 2% - 100%xI nominal |

| Charging Mode | Constant Voltage/Constant Current, Boost Charge, Float Charge |

| Efficiency | 85% - 95% (Depends on device specifications) |

| Response Time | 20msec. |

| Correction Time | 100msec - 200msec. |

| Protection Functions | |

| Over Temperature Protection | Electronic Over-temperature Protection (Fan cooling works at 50C. At 80C, the power to the load is cut.) |

| Surge Arrester | Surge Arrester Class-I or Class-II (optional) |

| Earth Leakage Protection | It monitors the isolation between DC(+) or DC(-) and ground. It gives an alarm in case of leakage. |

| Battery Reverse Polarity Protection(optional) | It prevents the Battery Circuit Breaker from being set up when the Battery is connected in reverse. |

| Management Panel and Communication Options | |

| Touchscreen Operator Panel | 7" Touch Color screen, Input Voltage, Output Voltage, Output Current, Boost Voltage, Float voltage, Boost Timer, Date-time, Status and Fault information, Parameter settings |

| Remote Management Interface (optional) | Browser-based remote management with Ethernet connection MOD-BUS RTU with RS485 connection |

| Environmental Conditions | |

| Operating temperature | -10 °C ~ +40 °C |

| Altitude Operating Height | 1.500m |

| Humidity | 90% none condensed |

| Acoustic Noise | < 55dB (at 1m distance and doors closed) |

| Cabinet Specifications | |

| Type–Protection Class | Free Standing Modular Cabinet, IP21 Indoor type (IP54 and higher protection class, Outdoor Type Cabinets are optional) |

| Paint–Color | Epoxy-Polyester Powder Paint - RAL 7035 |

| Soğutma | Forced air cooling with thermostat controlled fan |

| OPTION | CODE | DESCRIPTION |

|---|---|---|

| Non-standard input voltage value | xxxV | FLT series battery chargers can be produced at any required input voltage value that must be stated clearly by the order confirmation. |

| Adjustable output voltage | ADJ | Output voltage of FLT series battery chargers can be adjusted by the LCD panel. Maximum adjusting range is +/-30% |

| Non-standard frequency | FRQ | FLT series battery chargers are produced to function under 60 Hz network frequency. |

| Battery Output CB Protection | OCB | CB may be added to the battery charger to provide battery output |

| Load Output CB Protection | LCB | CB may be added to the battery charger to load output |

| Special Enclosure | K | FLT series battery chargers can be produced both INDOOR and OUTDOOR in special cabinets having different IPXX protection classes. |

| EMC Filter | EMC | Specially designed EMC-Filters can be added optionally to the both input and output of FLT series battery chargers. Filter specifications must be stated by offer/order. |

| Surge protector | ESD | High-Voltage Protection and Surge Arrester can be added to the both input and output of FLT series battery chargers. The required protection classes and the specifications (CLASS-I,CLASS-II,CLASS-III) must be given with the order. |

| Dry Contacts Output | C | Up to 21 Dry Contacts can be added for automotion and remote control. |

| Non-standard Input/Output terminal | T | According to the various customer needs. Input and output terminals can be designed and located specially on the cabinet. The required terminal drawings must be supplied together with the offer/order. |

| Special design and accessories | SPM | FLT series battery chargers can be designed specially with respect to direct customer needs and technical specifications. All special requirements and detailed technical drawings and specifications for accessories must be provided by the customer at the offer/order stage. |

| Remote Management Interface | RMU | Browser-based remote management with Ethernet connection MOD-BUS RTU with RS485 connection |

| Touchscreen Operator Panel (optional) | TSP | 7" Touch Color screen Input Voltage, Output Voltage, Output Current, Battery current, Boost Voltage, Float voltage, Boost Timer, LVD voltage, Date-time, Status and Fault information, Parameter settings |

| Parallel Connection and Load Sharing | PC | FLT battery chargers can be connected in parallel for redundancy and load sharing. Load balancing indicator can be added. |

| Battery Reverse Polarity Protection | BBP | It prevents the Battery Circuit Breaker from being set up when the Battery is connected in reverse. |

| Input VM/AM | IM | Analog / digital voltmeter or ammeter for input. |

| Output VM/AM | OM | Analog / digital voltmeter or ammeter for output. |

| Battery VM/AM | BM | Analog / digital voltmeter or ammeter for the batteries. |

|

Document Name

|

Download

|

|---|---|

| MRC | MRC English Catalog |